Funded by the West of England Mayoral Combined Authority (WEMCA) and UK Research Partnership Infrastructure Funding (UKRPIF), IAAPS has completed the installation of the UK-HyRES lab space connected to an on-site green hydrogen electrolyser facility at IAAPS, University of Bath, on the Bristol & Bath Science Park.

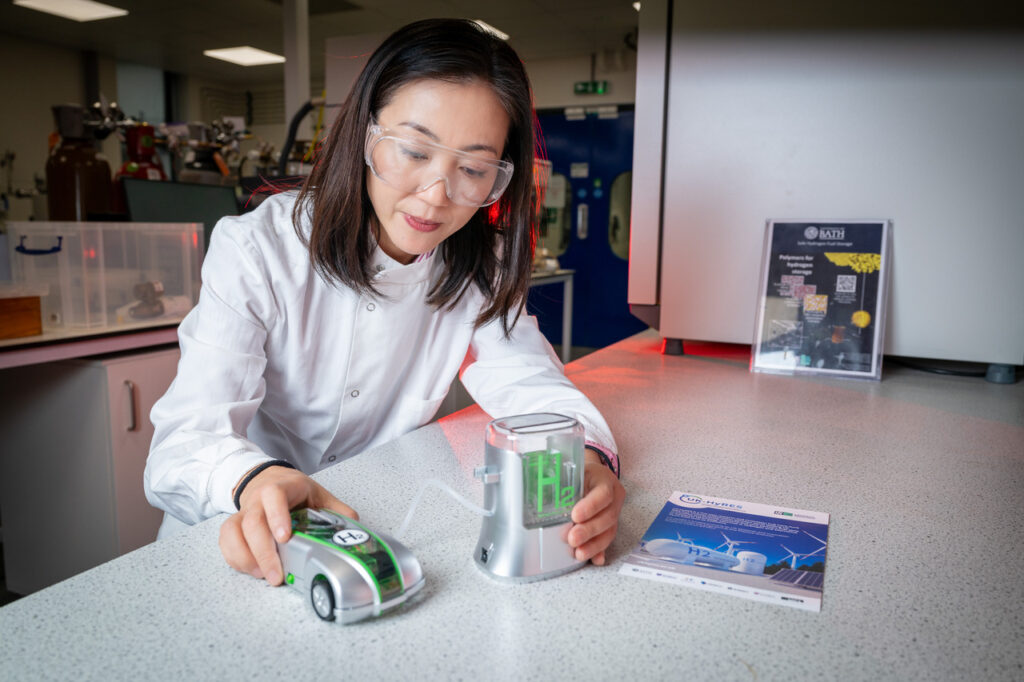

Adding to IAAPS’s extensive hydrogen testing capabilities, the new, soon-to-be fully operational facility, known as the UK-HyRES Research and Innovation Laboratory, will focus specifically on flexibility and smaller-scale, experimental hydrogen research.

The electrolyser facility produces up to 10 kg of hydrogen per hour and feeds into four specialist test environments, designed for hydrogen combustion and fuel cell research. Each research space is equipped with advanced hydrogen detection and ventilation systems to ensure maximum safety and flexibility.

Closing the gap between research and application

One of the major barriers to hydrogen innovation is access. Hydrogen research is costly and highly regulated due to stringent safety requirements. By centralising high-spec facilities at IAAPS, UK-HyRES opens the doors for more researchers and industrial partners to explore and scale hydrogen technologies safely.

Sam Akehurst, IAAPS Research Director working with Bath’s UK-HyRES project team, says: “We’re providing a space where researchers can safely test and scale up hydrogen technologies, from small-scale experiments to full propulsion systems. This approach bridges the gap between academic and industrial research, covering Technology Readiness Levels 1 to 9, enabling projects to move from lab-based discovery to industrial demonstration in a single location.

Looking ahead: cryogenics and liquid hydrogen

In addition to its hydrogen combustion and fuel cell capabilities, the UK-HyRES Lab is also advancing into cryogenic hydrogen research. The lab already has a cryogenic helium system operating at 20 K (–253 °C), supporting superconductivity research, a technology area of growing interest for the aviation sector.

Planning permission has also been granted to extend the facility to handle liquid hydrogen, paving the way for future developments in next-generation propulsion systems.

For more information about the facility, please contact Sam Akehurst or Chris Brace